✨ Introduction: Biodegradable Rotor Blade Materials in Helicopter Design

As the aviation industry continues to innovate, one of the most promising developments is the use of biodegradable materials in helicopter design. Helicopter rotor blades, being exposed to harsh elements and high wear and tear, typically rely on durable composite materials such as fiberglass and carbon fiber. However, with increasing pressure to make aviation more sustainable, researchers are exploring alternative materials that are not only durable but also biodegradable and environmentally friendly.

In this blog, we’ll explore how biodegradable rotor blade materials could revolutionize helicopter design, reduce the environmental impact of aviation, and contribute to the future of sustainable aviation.

🌍 What Are Biodegradable Rotor Blade Materials?

Biodegradable rotor blade materials are materials designed to decompose naturally without leaving harmful residues when exposed to environmental conditions like moisture, heat, and biological processes. These materials are eco-friendly alternatives to traditional composites, which are often non-biodegradable and can take hundreds of years to break down.

🌱 Biodegradable Materials in Helicopter Design

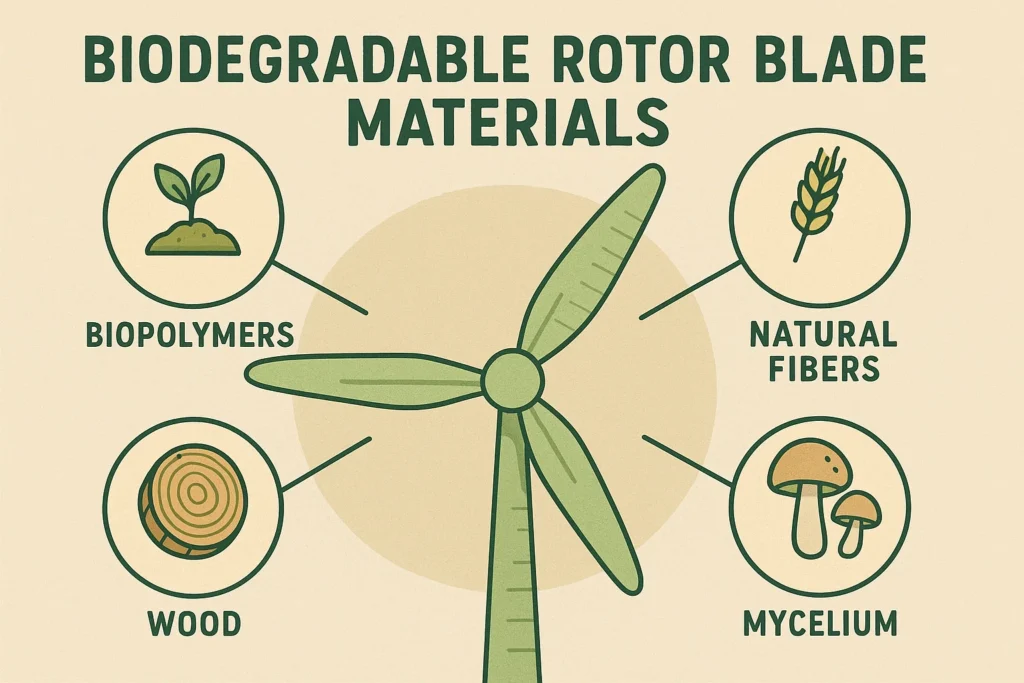

In helicopter design, biodegradable materials can be used in rotor blades and other parts of the aircraft to reduce the environmental footprint of aviation. These materials are typically made from renewable resources, such as plant fibers, biopolymers, and natural composites.

-

Natural Composites: These composites are made from plant fibers like hemp, flax, or jute, combined with biodegradable resins. They offer strength and durability similar to traditional composite materials.

-

Biopolymers: These are biodegradable plastics made from renewable resources like cornstarch or sugarcane. When used in helicopter rotor blades, they provide a more sustainable alternative to petroleum-based plastics.

🛫 How Biodegradable Rotor Blade Materials Can Benefit Helicopter Design

1. Environmental Sustainability

Traditional composite rotor blades, while strong and durable, can take centuries to break down when disposed of. In contrast, biodegradable materials decompose naturally, reducing the environmental impact of waste disposal.

-

Reduced Waste: Using biodegradable materials reduces the environmental impact of discarded helicopter components at the end of their lifecycle, contributing to zero-waste aviation.

-

Sustainable Manufacturing: Biodegradable rotor blades are often made from renewable resources, which further reduces the carbon footprint of helicopter manufacturing processes.

2. Lightweight Design

Many biodegradable materials are lighter than traditional composites, offering the potential for lighter rotor blades. A lighter rotor blade reduces the weight of the helicopter, which can lead to improved fuel efficiency and lower operational costs.

-

Increased Efficiency: Lighter materials contribute to better aerodynamics, reducing drag and improving overall fuel efficiency during flight.

3. Durability and Performance

Biodegradable materials are being engineered to offer performance characteristics that rival traditional materials. These materials can withstand the stress and wear encountered in rotor blades, providing long-lasting durability.

-

Strength and Resilience: Materials like natural composites offer high tensile strength and impact resistance, ensuring that rotor blades made from biodegradable materials meet the rigorous demands of helicopter operations.

4. Reduction in Carbon Footprint

By using renewable and biodegradable resources, helicopter manufacturers can lower the carbon emissions associated with rotor blade production and disposal.

-

Carbon Neutrality: The production of biodegradable rotor blades is less carbon-intensive compared to traditional materials like fiberglass and carbon fiber, contributing to more sustainable aviation.

🌍 Innovative Examples of Biodegradable Rotor Blade Materials

1. Airbus’s Composite and Bio-Resin Rotor Blades

Airbus is exploring the use of bio-resins for the construction of rotor blades. Bio-resins, derived from renewable resources like plant-based oils, are a more sustainable alternative to the petroleum-based resins traditionally used in helicopter rotor blades. These resins are biodegradable and offer excellent strength and flexibility, making them ideal for use in rotor blade construction.

-

Eco-Friendly Manufacturing: Airbus is collaborating with material suppliers to incorporate these biodegradable resins in the construction of rotor blades for future helicopters, reducing the environmental footprint of production.

For more information, visit Airbus.

2. Bell Helicopter’s Use of Natural Composites

Bell Helicopter has been experimenting with natural composites in their rotor blades. These composites, made from fibers such as hemp and flax, combined with biodegradable resins, are strong, lightweight, and more sustainable than traditional fiberglass-based rotor blades.

-

Eco-Friendly Testing: Bell Helicopter has conducted extensive testing on these natural composite materials, demonstrating their potential to reduce the environmental impact of helicopter components.

For more information, visit Bell Helicopter.

3. Sikorsky’s Composite Rotor Blade Research

Sikorsky, a leader in helicopter manufacturing, has been researching the use of bio-based composites in rotor blades. These composites are designed to offer the same strength and durability as traditional materials while being biodegradable at the end of their lifecycle.

-

Sustainable Alternatives: Sikorsky’s research is focused on creating long-lasting, environmentally friendly materials that can replace traditional composite rotor blades, contributing to more sustainable helicopter design.

For more information, visit Sikorsky.

🌍 Challenges and Opportunities of Biodegradable Rotor Blades

1. Material Limitations

While biodegradable materials show promise, there are still challenges related to strength, durability, and cost. Achieving the same level of performance as traditional materials requires further material innovation and testing.

-

Ongoing Research: Manufacturers are investing in R&D to improve the properties of biodegradable rotor blades, ensuring that they meet the high standards of helicopter safety and performance.

2. Manufacturing Costs

Currently, biodegradable materials may be more expensive to produce than traditional materials. However, as technology improves and production scales, these costs are expected to decrease, making sustainable materials more accessible for widespread use.

-

Cost Reduction: As demand for biodegradable materials increases, economies of scale will likely make these materials more affordable in the long term.

🌍 The Future of Biodegradable Rotor Blades in Helicopter Design

The use of biodegradable rotor blade materials is an exciting step toward achieving sustainable aviation. As technologies improve and more manufacturers embrace green materials, the future of helicopter design will increasingly rely on renewable, eco-friendly solutions that reduce carbon emissions and waste.

At DreamSafar, we are committed to providing innovative helicopter services that embrace sustainability. We are closely monitoring the latest developments in biodegradable materials and their potential applications in helicopter design, ensuring that we offer the most eco-friendly and cutting-edge aerial experiences for our customers.

🔗 Useful Links:

Resources:

❓ FAQ Section:

Q1: What are biodegradable rotor blades?

A1: Biodegradable rotor blades are helicopter blades made from materials that decompose naturally without leaving harmful residues. These materials are often derived from renewable resources like plant fibers or bio-resins, making them more eco-friendly than traditional materials.

Q2: How do biodegradable rotor blades benefit the environment?

A2: Biodegradable rotor blades reduce waste by breaking down naturally after their use, avoiding long-lasting environmental pollution. They also contribute to sustainable manufacturing by using renewable materials and lowering carbon emissions in production.

Q3: Are biodegradable rotor blades as strong as traditional ones?

A3: Yes, biodegradable rotor blades made from natural composites or bio-based resins are engineered to offer the same strength and durability as traditional materials while being lighter and more environmentally friendly.